What are the technological characteristics of low and high frequency pulse argon tungsten arc welding? Analysis of common use problems of tungsten electrode

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-29 17:28

- Views:

What are the technological characteristics of low and high frequency pulse argon tungsten arc welding? Analysis of common use problems of tungsten electrode

(Summary description)What are the technological characteristics of low-frequency pulsed argon tungsten arc welding?

Low-frequency pulse tungsten argon arc welding has the following technological characteristics.

1. During the duration of the pulse current, a spot-shaped molten pool is formed on the weldment; during the period of the pulse current stop, the base current can only maintain the stable combustion of the arc, the heat input to the weldment is significantly reduced, and the molten pool metal solidifies to form a welding spot. Therefore, the weld is composed of a series of weld points.

2. The arc is stable and the stiffness is good. When the current is small, general TIG welding is easy to arc, but pulsed TIG welding has good arc stiffness and stability, so this welding method is especially suitable for thin plate welding.

3. Low arc line energy. The pulse arc heats the workpiece centrally and has high thermal efficiency. Therefore, the average current required to penetrate the workpiece with the same thickness is about 20% lower than that of general tungsten arc welding, thereby reducing the heat input, which is beneficial to reduce the heat-affected zone and Reduce welding distortion.

4. Easy to control the weld formation. The welding pool has fast solidification speed and short high temperature residence time, so it can ensure a certain penetration depth, and is not easy to cause overheating, flow or burn-through, which is beneficial to realize single-sided welding without backing and double-sided welding and all-position welding.

5. The weld quality is good. Pulsed tungsten argon arc welding is formed by overlapping welding points, and the thermal cycle of subsequent welding points has a heat treatment effect on the previous welding point. At the same time, because the pulse current has a strong stirring effect on the spot molten pool, the cooling rate of the molten pool is fast, and the high temperature residence time is short, so the weld metal structure is fine and the dendrites are not obvious. These all make the weld performance improved.

What are the technological characteristics of high-frequency pulse argon tungsten arc welding?

The frequency range of the current is 10~20kHz. The process characteristics of this method are as follows.

①Suitable for high-speed welding

The high-frequency pulse arc has a large electromagnetic shrinkage effect and a good arc rigidity. It can avoid the bend or discontinuity of the weld bead caused by the adhesion of the anode spot during high-speed welding; avoid defects such as undercut and poor back forming. Therefore, it is especially suitable for high-speed automatic welding of thin plates.

②Big penetration

The arc pressure is large and the energy density is large, so the arc penetration capability is significantly increased.

③Good weld quality

The molten pool is subjected to ultrasonic vibration, its fluidity increases, and the physical and metallurgical properties of the welding are improved, which is conducive to the improvement of the quality of the weld.

④Suitable for large groove weld

In DC tungsten argon arc welding, if there are too many filler wires, the weld pool and the side of the groove will be poorly fused, and the weld bead will be raised and deflected to one side. When welding the next weld bead, poor melting on both sides of the weld bead easily leads to poor fusion or incomplete penetration. High-frequency pulse tungsten argon arc welding can well overcome this defect.

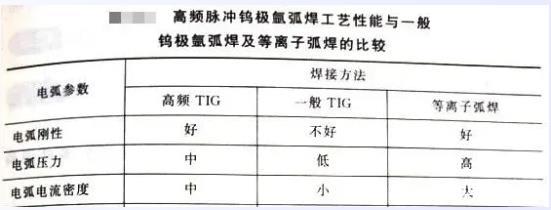

Many characteristics of high frequency argon tungsten arc welding are between general argon tungsten arc welding and plasma arc welding, see table

What are the technological characteristics of intermediate frequency pulsed argon tungsten arc welding?

The frequency range of the current is 10~500Hz. Its characteristic is that the arc is very stable under small current, and the arc force is not as high as high-frequency argon tungsten arc welding, so it is an ideal method for manual welding of thin plates below 0.5mm.

Development trend of argon arc welding tungsten electrode

Because of its high melting point and good high temperature performance, tungsten is the best material for electron emission and the best choice for argon arc welding starting electrodes. The earliest used tungsten argon arc welding electrode is a pure tungsten electrode, but the electron work function of the pure tungsten electrode is relatively high, about 4.52eV, and it is not easy to start arcing under the condition of small and medium currents. Therefore, all subsequent researches on electron emission materials are centered on reducing the work function of electrons. The earliest doped tungsten electrode material is thorium tungsten, which is doped with about 1-2% thorium oxide in the tungsten base. (This kind of thorium oxide was not prepared for argon arc welding at the beginning, but a material invented by an American named Pintsch to improve the brittleness of tungsten wires for light bulbs.)

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-29 17:28

- Views:

What are the technological characteristics of low-frequency pulsed argon tungsten arc welding?

Low-frequency pulse tungsten argon arc welding has the following technological characteristics.

1. During the duration of the pulse current, a spot-shaped molten pool is formed on the weldment; during the period of the pulse current stop, the base current can only maintain the stable combustion of the arc, the heat input to the weldment is significantly reduced, and the molten pool metal solidifies to form a welding spot. Therefore, the weld is composed of a series of weld points.

2. The arc is stable and the stiffness is good. When the current is small, general TIG welding is easy to arc, but pulsed TIG welding has good arc stiffness and stability, so this welding method is especially suitable for thin plate welding.

3. Low arc line energy. The pulse arc heats the workpiece centrally and has high thermal efficiency. Therefore, the average current required to penetrate the workpiece with the same thickness is about 20% lower than that of general tungsten arc welding, thereby reducing the heat input, which is beneficial to reduce the heat-affected zone and Reduce welding distortion.

4. Easy to control the weld formation. The welding pool has fast solidification speed and short high temperature residence time, so it can ensure a certain penetration depth, and is not easy to cause overheating, flow or burn-through, which is beneficial to realize single-sided welding without backing and double-sided welding and all-position welding.

5. The weld quality is good. Pulsed tungsten argon arc welding is formed by overlapping welding points, and the thermal cycle of subsequent welding points has a heat treatment effect on the previous welding point. At the same time, because the pulse current has a strong stirring effect on the spot molten pool, the cooling rate of the molten pool is fast, and the high temperature residence time is short, so the weld metal structure is fine and the dendrites are not obvious. These all make the weld performance improved.

What are the technological characteristics of high-frequency pulse argon tungsten arc welding?

The frequency range of the current is 10~20kHz. The process characteristics of this method are as follows.

①Suitable for high-speed welding

The high-frequency pulse arc has a large electromagnetic shrinkage effect and a good arc rigidity. It can avoid the bend or discontinuity of the weld bead caused by the adhesion of the anode spot during high-speed welding; avoid defects such as undercut and poor back forming. Therefore, it is especially suitable for high-speed automatic welding of thin plates.

②Big penetration

The arc pressure is large and the energy density is large, so the arc penetration capability is significantly increased.

③Good weld quality

The molten pool is subjected to ultrasonic vibration, its fluidity increases, and the physical and metallurgical properties of the welding are improved, which is conducive to the improvement of the quality of the weld.

④Suitable for large groove weld

In DC tungsten argon arc welding, if there are too many filler wires, the weld pool and the side of the groove will be poorly fused, and the weld bead will be raised and deflected to one side. When welding the next weld bead, poor melting on both sides of the weld bead easily leads to poor fusion or incomplete penetration. High-frequency pulse tungsten argon arc welding can well overcome this defect.

Many characteristics of high frequency argon tungsten arc welding are between general argon tungsten arc welding and plasma arc welding, see table

What are the technological characteristics of intermediate frequency pulsed argon tungsten arc welding?

The frequency range of the current is 10~500Hz. Its characteristic is that the arc is very stable under small current, and the arc force is not as high as high-frequency argon tungsten arc welding, so it is an ideal method for manual welding of thin plates below 0.5mm.

Development trend of argon arc welding tungsten electrode

Because of its high melting point and good high temperature performance, tungsten is the best material for electron emission and the best choice for argon arc welding starting electrodes. The earliest used tungsten argon arc welding electrode is a pure tungsten electrode, but the electron work function of the pure tungsten electrode is relatively high, about 4.52eV, and it is not easy to start arcing under the condition of small and medium currents. Therefore, all subsequent researches on electron emission materials are centered on reducing the work function of electrons. The earliest doped tungsten electrode material is thorium tungsten, which is doped with about 1-2% thorium oxide in the tungsten base. (This kind of thorium oxide was not prepared for argon arc welding at the beginning, but a material invented by an American named Pintsch to improve the brittleness of tungsten wires for light bulbs.) The incorporation of thorium oxide , Effectively enhance the electron emission ability of tungsten electrode, its electron work function is reduced to 2.63eV, so far, thorium tungsten electrode is still the most widely used tungsten electrode material. But thorium is a kind of radioactive material. Although thorium's radioactivity is relatively small, and its radiation amount is even smaller under the coating of tungsten, it does not conform to the current concept of environmental protection.

After thorium tungsten, all research on electrode materials is centered on not only avoiding radioactive hazards, but also infinitely approaching or even surpassing thorium tungsten materials in electron emission performance. In the research of this material, China is walking in the world. At the forefront, my country's material experts invented cerium-tungsten electrodes in the 1970s, and lanthanum-tungsten electrodes were widely used in the European market in the 1980s. The Soviet Union also first used yttrium-tungsten electrodes for argon arc welding from that era. Cerium-tungsten, lanthanum-tungsten, and yttrium-tungsten are electrode varieties developed by material experts in different countries to replace thorium-tungsten electrodes. The International Standards Organization formulated the ISO684 standard as early as 1984. Appearance, packaging, etc. have made relatively broad specifications. Our national standard for tungsten electrodes was formulated in 2015 and issued GB/T31908-2015, which was implemented on June 1, 2016. Since tungsten resources are China's advantageous resources, more than 90% of all types of tungsten materials in the world are produced in China. North Tungsten New Materials is one of the few domestic manufacturers that can produce all types of tungsten electrodes.

Existing grades of tungsten electrodes have their own advantages and disadvantages: thorium tungsten is a tungsten electrode with relatively comprehensive performance, but it is radioactive. The cerium tungsten electrode has the best arc starting performance, but its ability to carry large currents is relatively poor. The lanthanum tungsten electrode is resistant to burning However, in the preparation of lanthanum-tungsten materials, lanthanum-tungsten with low content such as WL15 (gold head) is not easy to start arcing, while high-content WL20 (blue head) material has a sharp decline in processing performance, is difficult to shape, and costs more. high. The advantage of yttrium tungsten electrode (WY20) is that the arc column is powerful, and it has advantages when the penetration depth is high. However, the material of yttrium is easy to volatilize at the high temperature of melting, resulting in poor welding sustainability. Pure tungsten and zirconium tungsten electrodes are only suitable for AC welding, and may not arc under DC conditions.

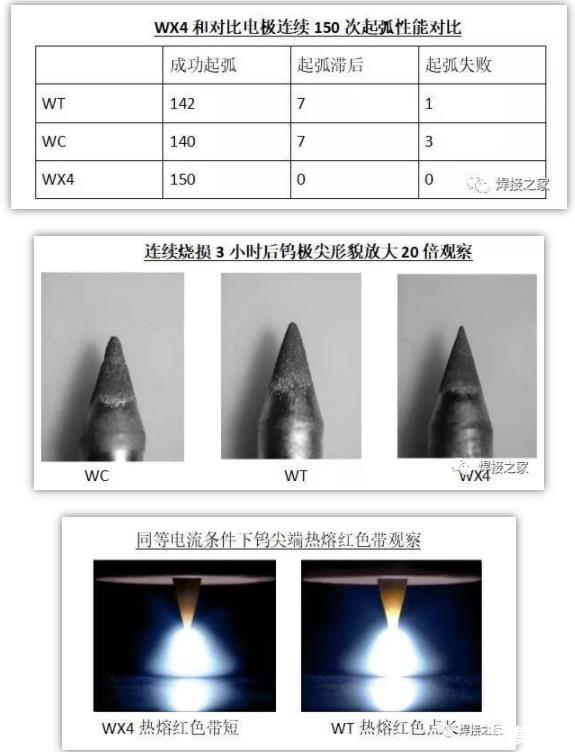

The tungsten electrode with a single addition of one element has proved that its performance cannot reach the full range, so the material experts adjusted the research direction to adding two or more rare earth elements, which proved to be effective in improving the welding performance of the tungsten electrode in an all-round way. At the end of the day, Osaka University, Japan, was the first to add two rare earth oxides. By 2006, the original Beijing Tungsten Molybdenum Material Factory and Beijing University of Technology tried to add three kinds of rare earth oxides in different proportions at the same time. Proved that its performance can fully surpass the thorium tungsten electrode. The E3 tungsten electrode, which became popular in the European and American markets in 2013, also belongs to the category of ternary composite tungsten electrode. However, the ternary electrode is excessively chased due to the excessive pursuit of burning resistance and the addition of lanthanum is too high. In the production process of the product, the yield rate is low and the selling price is high. In 2017, North Tungsten New Materials developed a WX4 brand tungsten electrode with four rare earth oxides added at the same time, which effectively took into account the relationship between welding performance and manufacturing cost, making it possible for this product to be quickly recognized and promoted by the market. Tested by the welding laboratory of Beijing University of Technology, the WX4 high-frequency arc starting success rate reached 100%, the current load can be increased by 20%, the tungsten electrode's burning resistance performance was increased by 30%, and it was also suitable for welding under AC and DC conditions. . The following is the test data of WX4 and comparison samples.

The reason why X4 can greatly improve product performance lies in the difference and complementary relationship between the diffusion rate and electron migration performance of the four rare earth oxides of lanthanum, cerium, yttrium and zirconium at different temperatures, which makes the tungsten electron emission performance Can get continuous play.

WX4 has been exported to Europe in batches with more than 1 million units, and its performance has been proven to be very superior. Starting from this year, we will vigorously promote WX4 in China, and hope that everyone can get strong support from the majority of distributors.

The key to the performance and stability of tungsten electrodes is not only the composition and formula, but also the uniformity of tungsten and the incorporated elements. There have always been two major technical schools in the blending process of two or more metal powders, one is Dry method, one is wet method. The so-called dry method, as the name implies, is to blend several powders. The wet method is to turn the blended metal into a liquid and then perform liquid-liquid blending or liquid-solid blending. After the water evaporates, a uniformly blended powder is obtained. The two processes have their own advantages and disadvantages, but the main points of the wet technology are difficult to grasp, and the cost is slightly higher. The North Tungsten New Material Company currently uses wet powder metallurgy technology. Dry technology can also obtain uniformly blended powder, but the process execution is relatively dependent on people and equipment.

Analysis of common problems in the use of tungsten electrode

1. It wears quickly, is not resistant to burning, "tungsten" or even the tungsten electrode melts.

reason:

(1) The current is high, which has exceeded the allowable current of the tungsten electrode of this diameter, which will easily cause the tungsten electrode to burn quickly or even melt.

(2) Tungsten electrode selection problem. For example, if you choose cerium-tungsten under the condition of communication, it is definitely possible to melt the electrode tip, or the diameter of the tungsten electrode selected is too small. It should be 2.4, and you chose 2.0.

(3) Improper sharpening of the tungsten electrode will also cause the tungsten electrode to melt. When the welding current is large, the use of a small diameter sharp angle will cause the current density to concentrate on the tungsten electrode tip and cause the tungsten electrode to easily burn or even melt.

(4) Welder's operating technique problems. The tip of the tungsten electrode and the base metal are easily burnt and passivated due to contact with the base metal. Frequent sharpening will cause the tungsten electrode to wear quickly.

(5) There is a small amount of low melting point metal in the mixing process of rare earth oxide and tungsten. The powder blending process has very high environmental requirements. If the low melting point metal is not properly controlled, it will cause tungsten. The extreme melting point is lowered in a cliff style, and the situation of ignition and melting will occur.

2. The tungsten electrode cannot be arced, or the arc column is erratic and weak after starting the arc, and the penetration depth cannot meet the requirements

reason:

(1) Wrong choice of tungsten electrode. Pure tungsten and zirconium tungsten are only suitable for welding under AC conditions, and there is no arc under common current.

(2) Rare earth oxides are mixed in a small amount. The role of rare earth oxides is to reduce the work function of electrons. If the amount is not enough, it will cause difficulty in arc starting. The thorium price has soared by 20 times in the first two years because of thorium ore control. As a result, if a manufacturer reduces the thorium content, it will actually make it difficult for the tungsten electrode to start arcing, and there is no power after arcing.

(3) Uneven mixing of rare earth oxides and tungsten

3. There is a "crack" sound during the welding process, or even the end burst

Reason: The tip of the tungsten electrode has splitting or air bubbles, which is caused by the mismatch of temperature and speed during the rotary forging and drawing process of the product.

4. After the tungsten electrode is used, it will be sharpened and flattened.

Reason: During the welding process, the tip of the tungsten electrode has been in a high-temperature recrystallization state, and the material after recrystallization becomes easy to break due to the coarse grains. So don't apply too much vertical force when sharpening.

5. Partial arc, scattered arc, erratic and weak arc column

reason:

(1) The method of sharpening the tungsten electrode is wrong. The sharpening of the tungsten electrode will cause arcing. The tungsten electrode wear scar is perpendicular to the electrode axis, and it will also cause arcing, especially under low current conditions. The misalignment of the tungsten electrode sharpening will cause the arc deviation, so the correct sharpening method is longitudinal sharpening.

(2) Uneven metal blending.

Source: Welding Technology, Welding Home

Note: All pictures in the article are reprinted on the Internet, and infringement will be deleted!

Tel: 0571-88780081

Mail: Firmkim@cn-huaguang.com

Fax: 0571-887 80081

Post code: 311112

Add: No. 7 Yaojia Road, Liangzhu Street, Yuhang District, Hangzhou City, Zhejiang Province (Huaguang New Materials)

Douyin QR code

We chat number

WeChat public account

©2021 Hangzhou Fujing Welding Technology Co., Ltd. all rights reserved 浙ICP备2021023610号-1 300.cn Hangzhou

-

WeChat

-

Telephone

- Service Hotline 0571-88780081

- TOP