How can the overhead welding technology be learned? The operation points and process of overhead welding

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-29 16:03

- Views:

How can the overhead welding technology be learned? The operation points and process of overhead welding

(Summary description)Because people are in an unnatural position during overhead welding, it is difficult to operate stably. At the same time, the heavy welding torch and cable must be lifted, which increases the difficulty of the operation. In addition, the molten iron in the molten pool is prone to sag during overhead welding, and it is easy to form a convex weld bead, which may cause the molten iron to flow in severe cases. Therefore, the welding parameters should be strictly controlled to get a good weld formation.

1. Single pass overhead welding

Thin plates are often welded on one side. In order to be welded through, a gap of 1.4~1.6mm should be left on the workpiece. Use thin welding wire (0.8~1.2mm in diameter) for short-circuit transfer welding, the welding current is 120~130A, and the arc voltage is 18~19V.

At this time, it should be in a straight line or a small swing, relying on the arc force and surface tension to maintain the molten pool. When the welding speed is too slow, the molten pool metal sags, and the surface of the weld bead appears uneven. In severe cases, the molten pool metal is lost. Therefore, you should always pay attention to the state of the molten pool during welding, and adjust the welding speed and swing mode in time. If the torch angle is too large, it will cause a convex weld bead and undercut.

2. Multi-layer overhead welding. When the workpiece is thick, multi-layer welding is required. When there is no backing plate, the first layer of welding bead is similar to single-sided welding. When there is a backing plate, there should be a certain gap between the workpieces, and the current can be slightly larger, but it is still a short-circuit transition. At this time, the welding current is 130~140A, and the arc voltage is 19~20V. During operation, the welding torch should be aligned with the center of the groove, and the welding torch should maintain the angle shown in Figure 2 and move at a constant speed in the right welding method.

At this time, it must be noted that the backing plate and the root of the groove should be fully penetrated, and there should be no convex weld bead. To this end, a small swing should be used, and a little stay on both sides of the weld bead, in order to obtain a flat weld bead, and create good conditions for the subsequent fill weld bead.

Both the 2nd and 3rd layers are welded in the form of a uniform swing welding gun, but a short stay should be made at the junction of the previous place and the groove surface to ensure full penetration and prevent undercut.

The welding parameters used at this time are the welding current 120~130A, and the arc voltage is 18~19V. After the 4th layer, because the width of the welding seam is too large, it is easy to produce incomplete penetration and pores when the swing is too large. Therefore, it is best to use the deposition method shown in Figure 3, that is, from the fourth layer onwards, each layer is welded with two weld passes.

In the two welds, the first weld bead should not be too wide, otherwise it will cause the weld bead to sag and the groove left for the second pass is too narrow, and it is easy to cause the second pass to form an incomplete and convex weld. So the first weld bead skips the center, and the second weld bead should overlap with the first weld bead.

The cover weld bead is a modified weld bead, which should be beautiful. First of all, make sure that the surface of the previous layer of the cover weld bead is flat, and the weld bead is about 1~2mm away from the surface of the workpiece. The cover weld bead is also completed with two welds; when welding these two welds, a little stay on both sides of the arc groove to prevent undercut and insufficient reinforcement. When welding the second weld bead, pay attention to the first One weld bead is evenly overlapped to prevent irregular weld bead height and width.

The welding parameters used at this time are relatively small, the welding current is 120~130A, and the arc voltage is 18~19V.

Operation points of overhead welding

1. Liquid metal falls due to its own weight. It is difficult to control the shape and size of the molten pool, which will cause incomplete penetration and depression. It is advisable to use a smaller diameter electrode, a small welding current and the shortest arc welding.

2. It is difficult to clean the slag, and it is easy to produce slag inclusion between layers.

3. It is difficult to transport the strips, and the appearance of the weld is not easy to be smooth

According to the characteristics of overhead welding, the arc length of the welding arc should be strictly controlled so that the roots on both sides of the groove can be well fused, and the thickness of the welding wave should not be too thick to prevent excessive liquid metal from falling. The groove angle is slightly larger than that of flat welding. The welding rod of the first layer of the groove and both sides of the groove are 90°, 70°~80° with the welding di

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-07-29 16:03

- Views:

Because people are in an unnatural position during overhead welding, it is difficult to operate stably. At the same time, the heavy welding torch and cable must be lifted, which increases the difficulty of the operation. In addition, the molten iron in the molten pool is prone to sag during overhead welding, and it is easy to form a convex weld bead, which may cause the molten iron to flow in severe cases. Therefore, the welding parameters should be strictly controlled to get a good weld formation.

1. Single pass overhead welding

Thin plates are often welded on one side. In order to be welded through, a gap of 1.4~1.6mm should be left on the workpiece. Use thin welding wire (0.8~1.2mm in diameter) for short-circuit transfer welding, the welding current is 120~130A, and the arc voltage is 18~19V.

At this time, it should be in a straight line or a small swing, relying on the arc force and surface tension to maintain the molten pool. When the welding speed is too slow, the molten pool metal sags, and the surface of the weld bead appears uneven. In severe cases, the molten pool metal is lost. Therefore, you should always pay attention to the state of the molten pool during welding, and adjust the welding speed and swing mode in time. If the torch angle is too large, it will cause a convex weld bead and undercut.

2. Multi-layer overhead welding. When the workpiece is thick, multi-layer welding is required. When there is no backing plate, the first layer of welding bead is similar to single-sided welding. When there is a backing plate, there should be a certain gap between the workpieces, and the current can be slightly larger, but it is still a short-circuit transition. At this time, the welding current is 130~140A, and the arc voltage is 19~20V. During operation, the welding torch should be aligned with the center of the groove, and the welding torch should maintain the angle shown in Figure 2 and move at a constant speed in the right welding method.

At this time, it must be noted that the backing plate and the root of the groove should be fully penetrated, and there should be no convex weld bead. To this end, a small swing should be used, and a little stay on both sides of the weld bead, in order to obtain a flat weld bead, and create good conditions for the subsequent fill weld bead.

Both the 2nd and 3rd layers are welded in the form of a uniform swing welding gun, but a short stay should be made at the junction of the previous place and the groove surface to ensure full penetration and prevent undercut.

The welding parameters used at this time are the welding current 120~130A, and the arc voltage is 18~19V. After the 4th layer, because the width of the welding seam is too large, it is easy to produce incomplete penetration and pores when the swing is too large. Therefore, it is best to use the deposition method shown in Figure 3, that is, from the fourth layer onwards, each layer is welded with two weld passes.

In the two welds, the first weld bead should not be too wide, otherwise it will cause the weld bead to sag and the groove left for the second pass is too narrow, and it is easy to cause the second pass to form an incomplete and convex weld. So the first weld bead skips the center, and the second weld bead should overlap with the first weld bead.

The cover weld bead is a modified weld bead, which should be beautiful. First of all, make sure that the surface of the previous layer of the cover weld bead is flat, and the weld bead is about 1~2mm away from the surface of the workpiece. The cover weld bead is also completed with two welds; when welding these two welds, a little stay on both sides of the arc groove to prevent undercut and insufficient reinforcement. When welding the second weld bead, pay attention to the first One weld bead is evenly overlapped to prevent irregular weld bead height and width.

The welding parameters used at this time are relatively small, the welding current is 120~130A, and the arc voltage is 18~19V.

Operation points of overhead welding

1. Liquid metal falls due to its own weight. It is difficult to control the shape and size of the molten pool, which will cause incomplete penetration and depression. It is advisable to use a smaller diameter electrode, a small welding current and the shortest arc welding.

2. It is difficult to clean the slag, and it is easy to produce slag inclusion between layers.

3. It is difficult to transport the strips, and the appearance of the weld is not easy to be smooth

According to the characteristics of overhead welding, the arc length of the welding arc should be strictly controlled so that the roots on both sides of the groove can be well fused, and the thickness of the welding wave should not be too thick to prevent excessive liquid metal from falling. The groove angle is slightly larger than that of flat welding. The welding rod of the first layer of the groove and both sides of the groove are 90°, 70°~80° with the welding direction. The shortest arc is used to push and pull back and forth, and the temperature of the molten pool is too high. When the temperature can be reduced. When welding the remaining layers, the electrode swings sideways and makes a steady arc action on both sides.

Overhead welding operation process

(1) During overhead welding, care must be taken to use the shortest arc length as much as possible for welding, so that the molten metal will be transferred from the electrode to the molten pool in a short time, and the weld will be formed. The diameter of the electrode and the welding current should be smaller than during flat welding to reduce the area of the weld pool and make the weld easy to form.

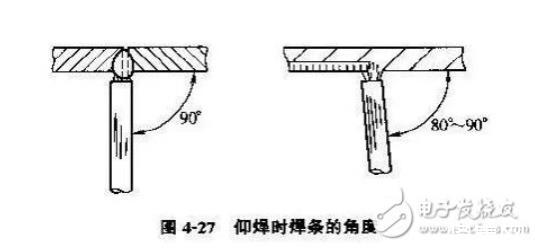

(2) When the thickness of the weldment is about 4mm, butt welding without grooves can be used for overhead welding. The diameter of the electrode is 3.2mm, and the angle between the electrode and both sides of the weld is 90°, and the welding direction is maintained at 80°- The included angle of 90° is shown in Figure 4-27. During the entire welding process, the welding rod should be kept at the above-mentioned angle and transported evenly.

(3) Overhead welding can adopt linear and linear reciprocating methods. The straight shape is used for welding joints with small gaps, and the linear reciprocating shape is used for joints with larger gaps. The welding current should not be too small, otherwise sufficient penetration will not be obtained, and the arc is also unstable, making the operation difficult to master, and the quality of the weld is difficult to guarantee.

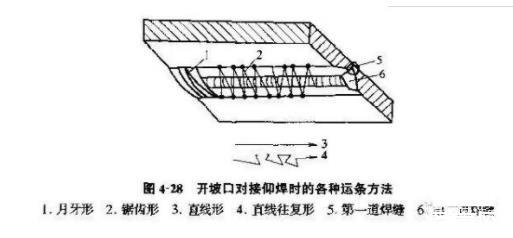

(4) When the thickness of the weldment is greater than 5mm, the butt and overhead welding shall be grooved. For the strip transportation method of open bevel butt butt welding and bottom layer welding, the choice of linear or reciprocating linear strip transport method should be selected according to the size of the groove gap. Afterwards, zigzag or crescent-shaped strips should be used for each layer. As shown in Figure 4-28. When carrying out overhead welding, no matter which method is used, a thinner weld bead should be formed. The surface of the weld seam should be straight and no convex shape is allowed.

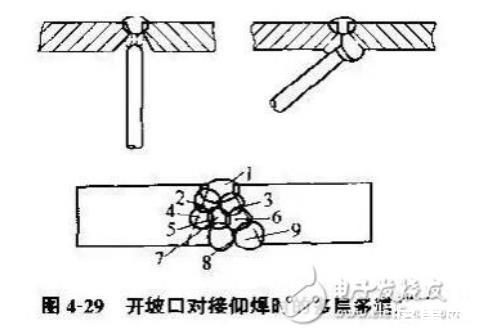

(5) Figure 4-29 shows the arrangement sequence of the multi-layer and multi-pass welding seams in the butt-joint overhead welding. During operation, the angle of the electrode should be adjusted according to the position of each weld to facilitate the transition of the droplet metal and to obtain a better weld formation.

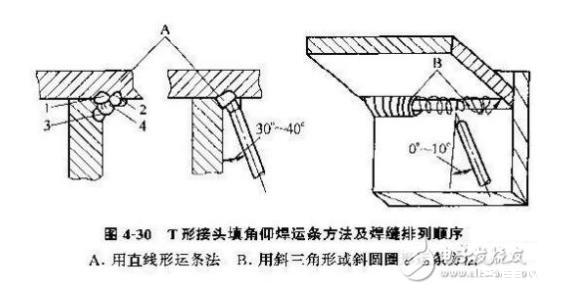

(6) The fillet overhead welding of the T-shaped interface is easier to master than the butt groove overhead welding. When the size of the welding foot is less than 6mm, single-layer welding is used, and the method of linear or reciprocating linear transportation is used. When the size of the welding foot is greater than 6mm, multi-layer and multi-pass welding is used. The first layer uses the method of linear transportation. The subsequent layers can be transported by oblique diagonal or oblique ring.

The transportation method of fillet overhead welding for T-shaped joints is shown in Figure 4-30. If you are skilled in fillet overhead welding, you can use a larger diameter electrode and a slightly larger welding current to improve work efficiency. Because people are in an unnatural position during overhead welding, it is difficult to operate stably. At the same time, the heavy welding torch and cable must be lifted, which increases the difficulty of the operation. In addition, the molten iron in the molten pool is prone to sag during overhead welding, and it is easy to form a convex weld bead, which may cause the molten iron to flow in severe cases. Therefore, the welding parameters should be strictly controlled to get a good weld formation.

来源:焊接技术,电子发烧友

注:文章内的所有配图皆为网络转载图片,侵权即删!

Tel: 0571-88780081

Mail: Firmkim@cn-huaguang.com

Fax: 0571-887 80081

Post code: 311112

Add: No. 7 Yaojia Road, Liangzhu Street, Yuhang District, Hangzhou City, Zhejiang Province (Huaguang New Materials)

Douyin QR code

We chat number

WeChat public account

©2021 Hangzhou Fujing Welding Technology Co., Ltd. all rights reserved 浙ICP备2021023610号-1 300.cn Hangzhou

-

WeChat

-

Telephone

- Service Hotline 0571-88780081

- TOP