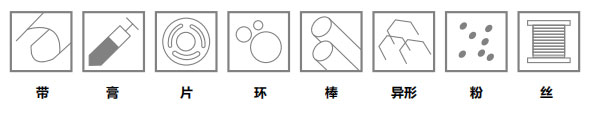

Product Categories

Vacuum solder

Production ability

Element symbol

| Cu | copper |

Zn

|

Zinc |

In

|

indium |

|

P

|

phosphorus |

Ni

|

nickel |

Sn

|

tin |

|

Ag

|

silver |

Mn

|

manganese |

Si

|

silicon |

Vacuum brazing filler metal has excellent process performance, suitable melting point, good wettability and gap filling performance. The brazing filler metal has good plasticity, excellent conductivity, and high mechanical strength of brazing joints. It can be used for brazing various materials such as copper alloys, titanium alloys, stainless steel, carbon steel, and hard alloys. The vacuum brazing filler metal is usually welded in a vacuum furnace or used with a brazing flux to obtain excellent joints.

:Copper alloy

:Copper alloy  :black metal

:black metal  :Nickel-plated ceramics

:Nickel-plated ceramics

Note: All product specifications, dimensions and ingredients support customization

| Grade | performance | Base material | Preform | introduce | |||||

|

Element /wt.%

|

|||||||||

|

FirmKim

|

BAg50Cu

|

Ag

|

Cu

|

-

|

-

|

C

|

|

Has a low silver content, suitable for Vacuum welding products, such as vacuum Arc extinguishing chamber, magnetron, electron emission Tubes, discharge tubes and other products |

|

|

GB/T 10046

|

-

|

49~51

|

Remain |

-

|

-

|

F

|

|

||

|

AWS A5.8

|

BVAg-6b

|

Melting temperature/℃

|

Gap caulking/mm

|

NF |   |

||||

|

ISO 17672

|

-

|

750~860

|

0.02~0.20

|

|

|||||

|

FirmKim

|

BAg72Cu

|

Ag

|

Cu

|

-

|

-

|

C

|

|

Has a lower welding temperature, suitable for For vacuum welding products, such as vacuum Arc extinguishing chamber, magnetron, electron emission Tubes, discharge tubes and other products |

|

|

GB/T 10046

|

BAg72Cu/HL308

|

71~73

|

27~29

|

-

|

-

|

F

|

|

||

|

AWS A5.8

|

BVAg-8

|

Melting temperature/℃

|

Gap caulking/mm

|

NF

|

|

||||

|

ISO 17672

|

Ag 272

|

779~779

|

0.02~0.20

|

|

|||||

|

FirmKim

|

BAg72CuNi

|

Ag

|

Cu

|

Ni

|

-

|

C

|

|

Has better wettability, strong welding High degree, suitable for vacuum welding Products, such as vacuum interrupter, magnetron Tube, electron emission tube, discharge tube, etc. product |

|

|

GB/T 10046

|

-

|

70~72

|

Remain |

0.5~1.0

|

-

|

F

|

|

||

|

AWS A5.8

|

-

|

Melting temperature/℃

|

Gap caulking/mm

|

NF |   |

||||

|

ISO 17672

|

-

|

770~830

|

0.03~0.20

|

|

|||||

Tel: 0571-88780081

Mail: Firmkim@cn-huaguang.com

Fax: 0571-887 80081

Post code: 311112

Add: No. 7 Yaojia Road, Liangzhu Street, Yuhang District, Hangzhou City, Zhejiang Province (Huaguang New Materials)

Douyin QR code

We chat number

WeChat public account

©2021 Hangzhou Fujing Welding Technology Co., Ltd. all rights reserved 浙ICP备2021023610号-1 300.cn Hangzhou

-

WeChat

-

Telephone

- Service Hotline 0571-88780081

- TOP