Product Categories

Aluminum solder

:Aluminum alloy :Aluminum alloy

Note: All product specifications, dimensions and ingredients support customization

Grade

performance

Base material

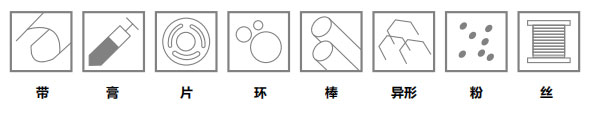

Preform

introduce

Element /wt.%

FirmKim

4047

Al

Si

A

Mainly used for brazing between aluminum and aluminum alloy,

Can use flame brazing, induction brazing, furnace

Brazing is performed by brazing, vacuum brazing and other methods.

GB/T 13815

BAl88Si

Remain

11~13

A

AWS A5.8

BAlSi-4

Melting temperature/℃

ISO 17672

Al112

575~585

FirmKim

ZnAl22

Al

Zn

A

Brazing between copper alloy and aluminum alloy, suitable for

Used in transformers, refrigeration industry and other fields.

GB/T 13815

-

22

78

A

AWS A5.8

-

Melting temperature/℃

ISO 17672

-

410~485

FirmKim

ZnAl2

Al

Zn

A

Brazing and brazing between copper alloys and aluminum alloys

Low temperature, especially suitable for refrigeration industry chain, etc.

field.

GB/T 13815

-

2

98

A

AWS A5.8

-

Melting temperature℃

ISO 17672

-

385~405

Production ability

Element symbol

| Cu | copper |

Zn

|

Zinc |

In

|

indium |

|

P

|

phosphorus |

Ni

|

nickel |

Sn

|

tin |

|

Ag

|

silver |

Mn

|

manganese |

Si

|

silicon |

Aluminum solder has good wettability and joint filling properties, low melting point, and corrosion resistance. Among them, aluminum-silicon solder and zinc-aluminum solder are more commonly used. Zn-Al solder is usually combined with CsAlF4 eutectic solder to make flux core solder, which is widely used in aluminum-copper joints of transformers and aluminum-copper joints in the refrigeration industry. Al Si eutectic-based brazing filler metal is mainly used for brazing aluminum and aluminum alloys. When brazing copper, nickel is usually plated on the copper surface to reduce the influence of brittle compounds between aluminum and copper. Flame brazing, induction brazing, furnace brazing, vacuum brazing and other methods are used for brazing to obtain corrosion resistance. Better joints.

:Aluminum alloy

:Aluminum alloy  :Aluminum alloy

:Aluminum alloy

Note: All product specifications, dimensions and ingredients support customization

| Grade | performance | Base material | Preform | introduce | ||||

|

Element /wt.%

|

||||||||

|

FirmKim

|

4047

|

Al

|

Si

|

A

|

|

Mainly used for brazing between aluminum and aluminum alloy, Can use flame brazing, induction brazing, furnace Brazing is performed by brazing, vacuum brazing and other methods. |

||

|

GB/T 13815

|

BAl88Si

|

Remain |

11~13

|

A

|

|

|||

|

AWS A5.8

|

BAlSi-4

|

Melting temperature/℃

|

|

|||||

|

ISO 17672

|

Al112

|

575~585

|

||||||

|

FirmKim

|

ZnAl22

|

Al

|

Zn

|

A

|

|

Brazing between copper alloy and aluminum alloy, suitable for Used in transformers, refrigeration industry and other fields. |

||

|

GB/T 13815

|

-

|

22

|

78

|

A

|

|

|||

|

AWS A5.8

|

-

|

Melting temperature/℃

|

|

|

||||

|

ISO 17672

|

-

|

410~485

|

||||||

|

FirmKim

|

ZnAl2

|

Al

|

Zn

|

A

|

|

Brazing and brazing between copper alloys and aluminum alloys Low temperature, especially suitable for refrigeration industry chain, etc. field. |

||

|

GB/T 13815

|

-

|

2

|

98

|

A

|

|

|||

|

AWS A5.8

|

-

|

Melting temperature℃

|

|

|||||

|

ISO 17672

|

-

|

385~405

|

||||||

Tel: 0571-88780081

Mail: Firmkim@cn-huaguang.com

Fax: 0571-887 80081

Post code: 311112

Add: No. 7 Yaojia Road, Liangzhu Street, Yuhang District, Hangzhou City, Zhejiang Province (Huaguang New Materials)

Douyin QR code

We chat number

WeChat public account

©2021 Hangzhou Fujing Welding Technology Co., Ltd. all rights reserved 浙ICP备2021023610号-1 300.cn Hangzhou

-

WeChat

-

Telephone

- Service Hotline 0571-88780081

- TOP