Products

PRODUCT CATEGORY

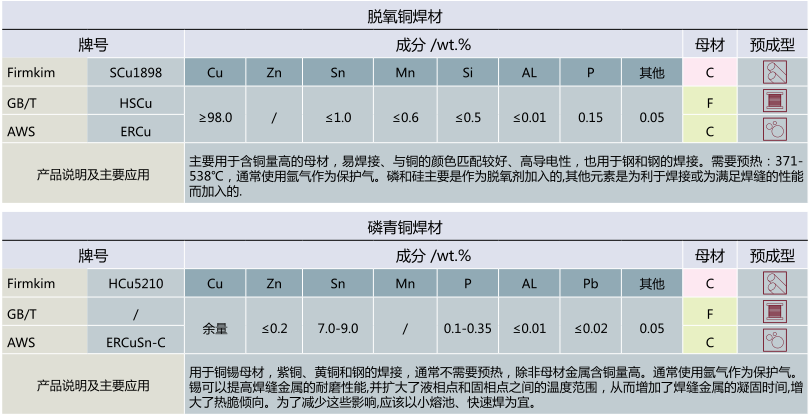

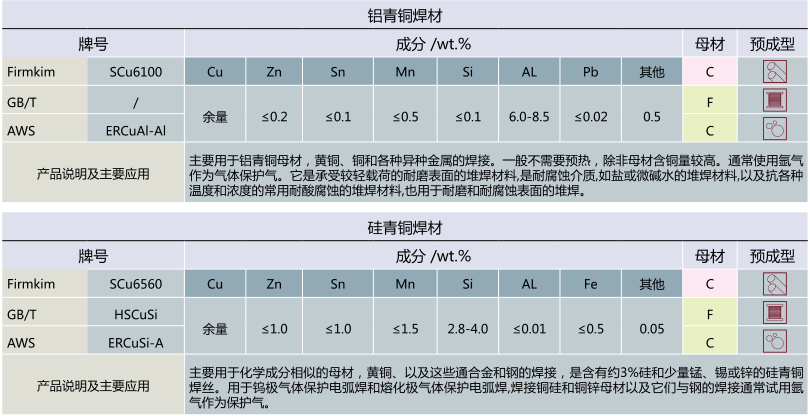

Copper Alloy Welding Material

Copper and copper alloy welding with Welding materials wire, welding rod, flux, solvent, shielding gas, etc., in the copper alloy wire to join aluminum, silicon, manganese, phosphorus, tin and other elements, in order to strengthen the deoxidation, reduce the porosity in the weld. In addition to deoxidation, aluminum can also refine the weld grain and improve the plasticity and toughness of the weld metal. But the deoxidizer should not be too much, otherwise the weld will form too much high melting point oxidation inclusions.

Classification:

E-mail: Firmkim@cn-huaguang.com

Contact UsProduct Description

Tag:

Copper Alloy Welding Material

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:18594983359