Products

PRODUCT CATEGORY

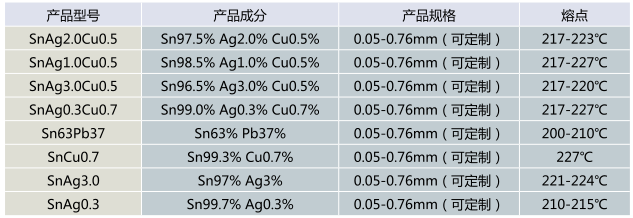

BGA Tin Ball

BGA solder balls are special solder balls used on the solder board before soldering the integrated circuit of the BGA package. The specific use method is to cover the newly bought chip with solder paste on the BGA tin net, put the BGA tin ball, blow it with a hot air gun, take out the BGA tin net when it is soldered on the chip, and solder the chip with the BGA tin ball on the circuit board with the BGA soldering station.

Classification:

E-mail: Firmkim@cn-huaguang.com

Contact UsProduct Description

Tag:

BGA Tin Ball

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:18594983359