Products

PRODUCT CATEGORY

Product Description

Tag:

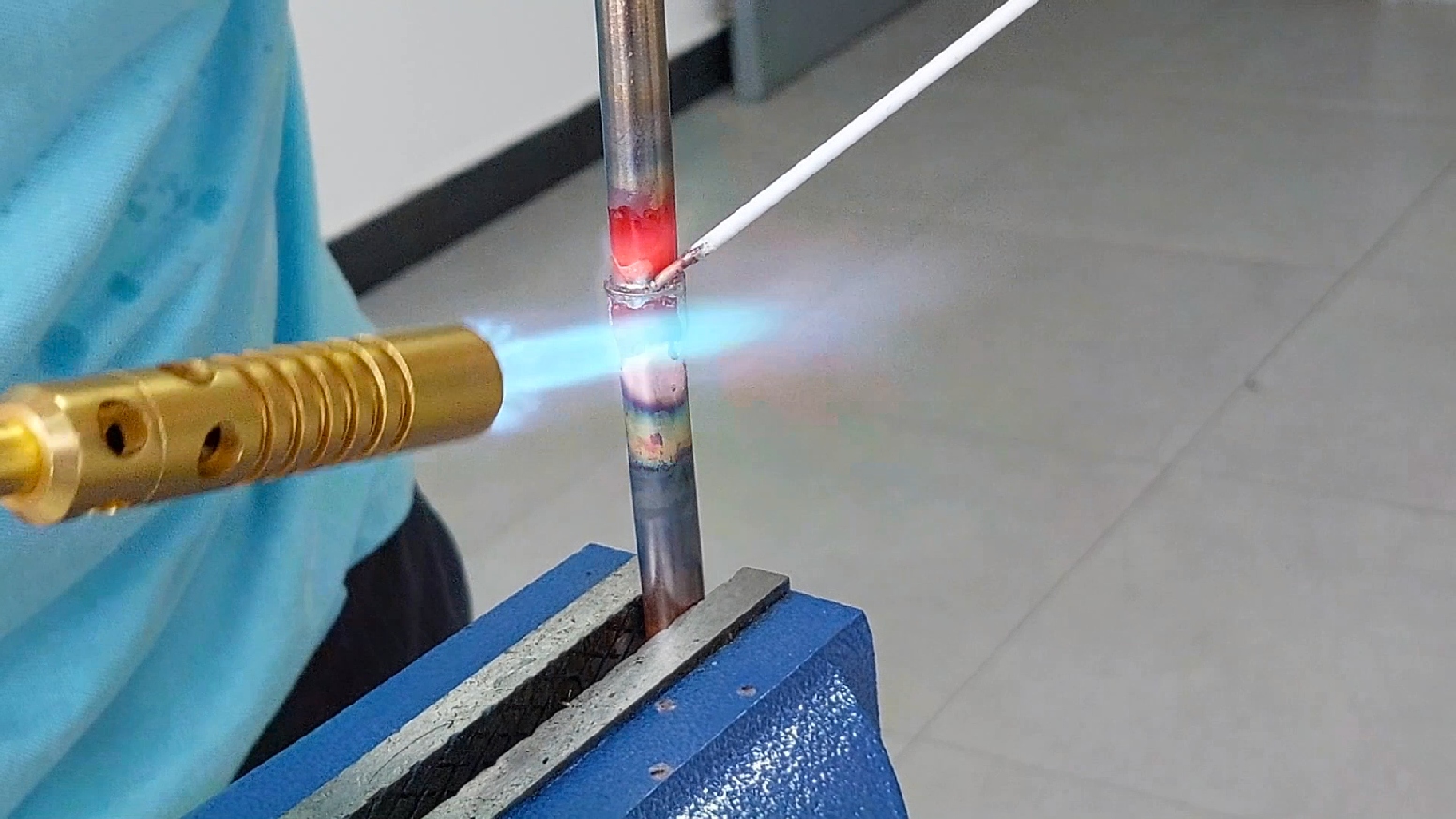

Flame brazing processing

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:18594983359