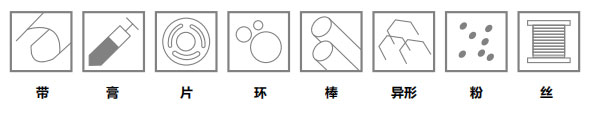

Product Categories

Brass solder

Production ability

Element symbol

| Cu | copper |

Zn

|

Zinc |

In

|

indium |

|

P

|

phosphorus |

Ni

|

nickel |

Sn

|

tin |

|

Ag

|

silver |

Mn

|

manganese |

Si

|

silicon |

Brass brazing filler metal is mainly used for rapid heating brazing processes such as flame brazing, high frequency induction brazing and resistance brazing. It can braze copper, copper alloys, steel, cast iron, and hard alloys. Before brazing, the grease, oxides and other contaminants on the metal brazing surface must be strictly removed. When brazing, it needs to be used in conjunction with flux to obtain a stable and reliable joint.

:Red copper

:Red copper  :black metal

:black metal  :Cemented carbide

:Cemented carbide

Note: All product specifications, dimensions and ingredients support customization

| Grade | performance | Base material | Preform | main application | |||||||

|

Element /wt.%

|

|||||||||||

|

FirmKim

|

RCuZn-A

|

Cu

|

Zn

|

Si

|

Sn

|

Fe

|

- | - | C |   |

The solder contains Sn and Si to improve The solder wettability can be at the same time Prevent volatilization of Zn during brazing. |

|

GB/T 6418

|

- |

56~64

|

Remain |

<0.5

|

<1.0

|

<0.25

|

- | - | F |   |

|

|

AWS A5.8

|

- |

Melting temperature/℃

|

Gap caulking/mm

|

- | - | C |   |

||||

|

ISO 17672

|

- |

870~900

|

0.05~0.25

|

- | - |   |

|||||

|

FirmKim

|

RCuZn-C

|

Cu

|

Zn

|

Si

|

Mn

|

Sn

|

Fe

|

- | C |   |

Contains Fe and Mn, can improve the brazing seam Strength and hardness, can be used for brazing Material process performance and brazing seam strength More demanding occasions. |

|

GB/T 6418

|

BCu58ZnFeSn(Si)

(Mn)

|

56~64

|

Remain |

0.01~0.5

|

0.01~0.5

|

0.75~1.105

|

0.25~1.25

|

- | F |   |

|

|

AWS A5.8

|

C68100

|

Melting temperature/℃

|

Gap caulking/mm

|

- | - | C |   |

||||

|

ISO 17672

|

Cu681

|

870~900

|

0.05~0.25

|

- | - |   |

|||||

|

FirmKim

|

RCuZn-D

|

Cu

|

Zn

|

Si

|

Mn

|

Sn

|

Fe

|

Ni

|

C |   |

Contains higher Ni, which can improve the Gold plasticity, improve the solder in hard bonding The wettability of gold, especially suitable for Brazing hard alloy, can also be used for steel And nickel alloys have more requirements for corrosivity High brazed joints. |

|

GB/T 6418

|

- |

46~50

|

Remain |

0.04~0.15

|

<0.5

|

<0.5

|

<0.5

|

9~11

|

F |   |

|

|

AWS A5.8

|

C77300

|

Melting temperature/℃

|

Gap caulking/mm

|

C |   |

||||||

|

ISO 17672

|

- |

920~940

|

0.05~0.25

|

|

|||||||

|

FirmKim

|

BCu60Zn(Si)

|

Cu

|

Zn

|

Si

|

- | - | - | - | C |   |

The solder is relatively simple and contains Si element, Can prevent volatilization and wetting of Zn Sex is slightly worse. |

|

GB/T 6418

|

BCu60Zn(Si)

|

58.5~61.5

|

Remain |

0.2~0.4

|

- | - | - | - | F |   |

|

|

AWS A5.8

|

- |

Melting temperature/℃

|

Gap caulking/mm

|

C |   |

||||||

|

ISO 17672

|

Cu470a

|

875~895

|

0.05~0.25

|

|

|||||||

|

FirmKim

|

BCu59Zn(Sn)

|

Cu

|

Zn

|

Sn

|

- | - | - | - | C |   |

The solder contains Sn, which has better Wettability. |

|

GB/T 6418

|

BCu59Zn(Sn)

|

57~61

|

Remain |

0.2~0.5

|

- | - | - | - | F |   |

|

|

AWS A5.8

|

- |

Melting temperature/℃

|

Gap caulking/mm

|

C |   |

||||||

|

ISO 17672

|

Cu470

|

875~895

|

0.05~0.25

|

|

|||||||

Tel: 0571-88780081

Mail: Firmkim@cn-huaguang.com

Fax: 0571-887 80081

Post code: 311112

Add: No. 7 Yaojia Road, Liangzhu Street, Yuhang District, Hangzhou City, Zhejiang Province (Huaguang New Materials)

Douyin QR code

We chat number

WeChat public account

©2021 Hangzhou Fujing Welding Technology Co., Ltd. all rights reserved 浙ICP备2021023610号-1 300.cn Hangzhou

-

WeChat

-

Telephone

- Service Hotline 0571-88780081

- TOP