Products

PRODUCT CATEGORY

Solder paste

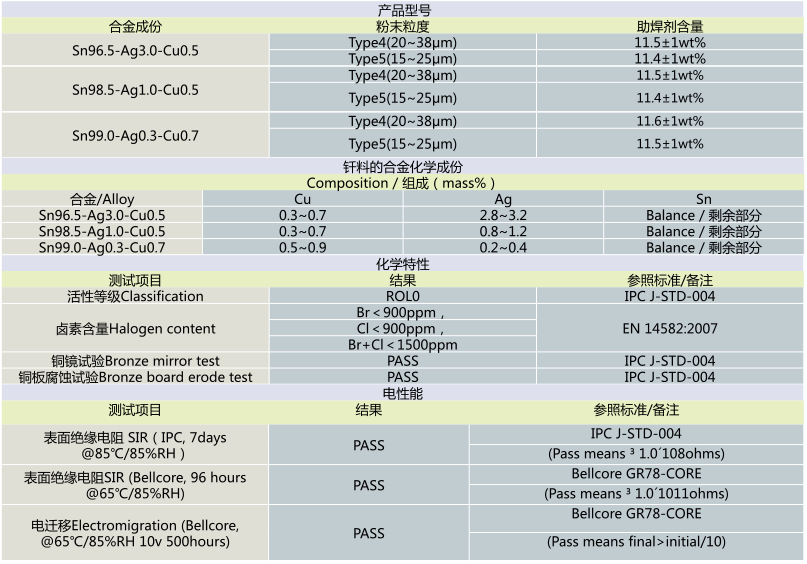

HG-X100A is a lead-free and non-cleaning solder paste, which has a wide process window and low void defects. It is compatible with Sn96.5-Ag3.0-Cu0.5, Sn98.5-Ag1.0-Cu0.5 and Sn99.0-Ag0.3-Cu0.7 alloys and is suitable for reflow soldering process of precision electronic devices. This product can achieve the requirements of stable fine-pitch printing ability, and has excellent online test performance for air-raid shelters and headrest defects. HG-X100A can ensure excellent continuity of printing, anti-collapse ability, surface insulation resistance performance. Lower residue after welding can ensure the passing of ICT needle measurement. The HG-X100A has excellent anti-drying ability, can still guarantee more than 8 hours under continuous printing conditions, and the solder paste has good adhesion.

Classification:

E-mail: Firmkim@cn-huaguang.com

Contact UsProduct Description

Tag:

Solder paste

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:18594983359