Products

PRODUCT CATEGORY

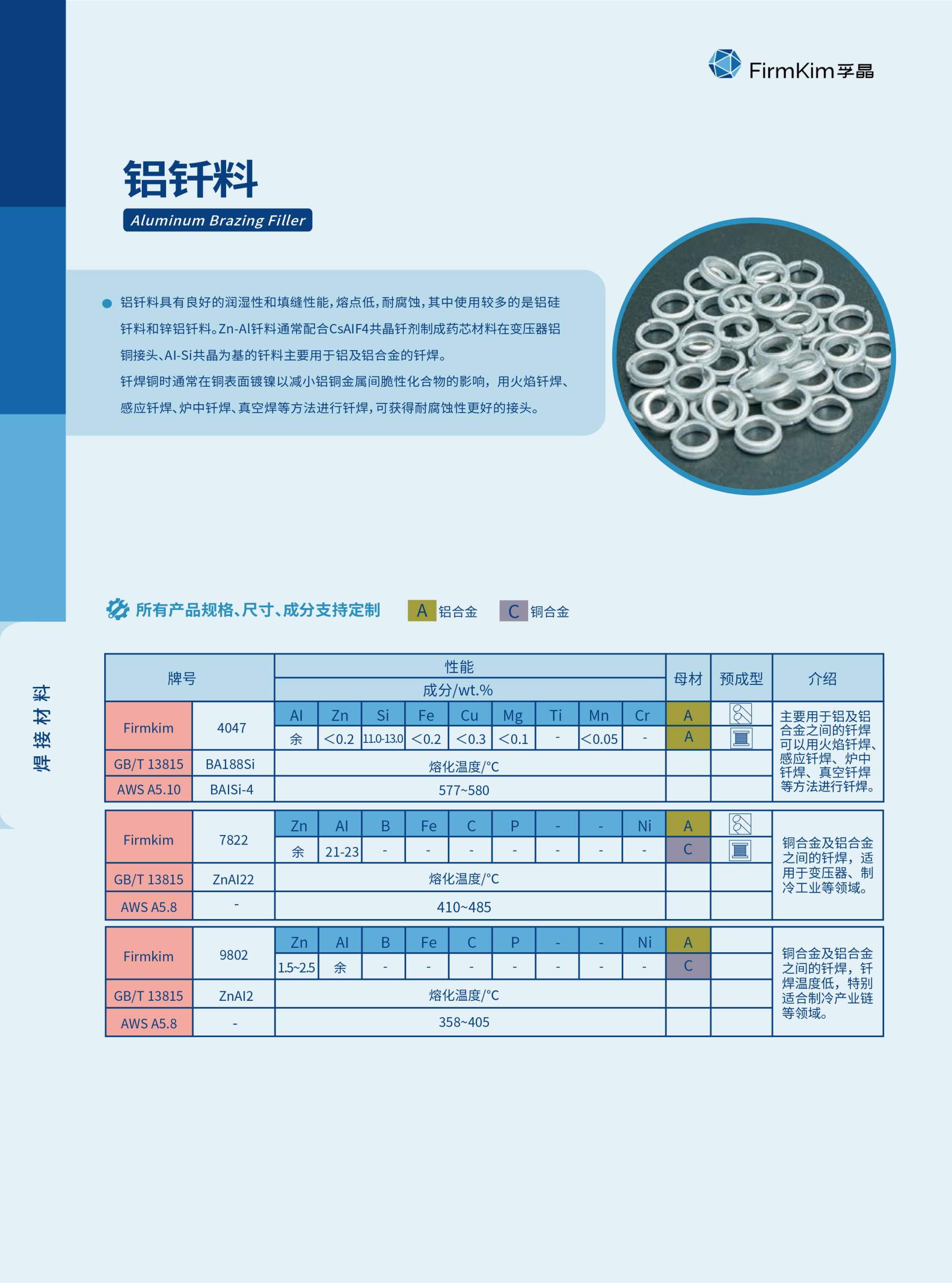

Aluminum brazing filler metal

Aluminum solder has good wettability and caulking performance, low melting point, corrosion resistance, which use more aluminum-silicon solder and zinc-aluminum solder. Zn-Al solder is usually made of flux-cored solder with CsAlF4 eutectic solder, which is widely used in transformer aluminum-copper joints and aluminum-copper joints in refrigeration industry. Al-Si eutectic-based brazing filler metals are mainly used for brazing aluminum and aluminum alloys. When brazing copper, nickel is usually plated on the copper surface to reduce the influence of aluminum-copper intermetallic brittle compounds, and the joints with better corrosion resistance can be obtained by brazing with flame brazing, induction brazing, furnace brazing, vacuum brazing and other methods.

Classification:

E-mail: Firmkim@cn-huaguang.com

Contact UsProduct Description

Tag:

Aluminum brazing filler metal

Related Products

Get free product quotes

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:18594983359