Hangzhou Fujing Welding Technology Co., Ltd简介

Release time:

2022-03-10

【Summary Description】 Hangzhou Fujing Welding Technology Co., Ltd was established in 2007 and is a wholly-owned subsidiary of Hangzhou Huaguang New Welding Materials Co., Ltd. (stock code: 688379), the first listed company in the field of brazing materials in China. The company can quickly provide customized products and technical services according to different application scenarios of customers.

HangzhouFujing weldingTechnology Company Limited

Hangzhou Fujing Welding Technology Co., Ltd成立于In 2007, it is a wholly-owned subsidiary of Hangzhou Huaguang Welding New Materials Co., Ltd. (stock code: 688379), the first listed company in the field of brazing materials in China.

The company can quickly provide customized products and technical services according to different application scenarios of customers.

Fujing's products include various types of Welding materials, Welding tools, welding equipment, welding parts processing and other types of welding supporting products. In terms of technical services, Fujing can provide customers with systematicWelding-related consulting and training services, Welding materials selection, welding process design, welding scheme evaluation and optimization, composition and physical performance testing.

Enterprise Profile

Hangzhou Fujing Welding Technology Co., Ltd has become an excellent one-stop welding overall solution professional service provider. Through Fujing, customers can obtain professional welding services quickly, effectively and accurately.

Fujing can quickly provide customized products and technical services according to different application scenarios of customers. Welding materials selection, welding process design, welding program evaluation and optimization, composition and physical performance testing.

Has been in the refrigeration industry chain, home appliances, automobiles, electromechanical,Tools, sanitary ware, glasses, special machinery and equipment, electronic information industry, high-end precision valves and new energy equipment and other fields to accumulate application cases. Fu Jing to efficient, environmentally friendly and intelligent green welding products.

Make welding simple and safe;

Let customers worry, rest assured.

Enterprise culture

Business Purpose

Customer-centric, focusing on customer needs and challenges, to create a collaborative platform for the welding industry chain;

Make welding simple and safe;

Let customers worry, rest assured.

Enterprise slogan

Your welding expert

Corporate Vision

Become a one-stop welding overall solution professional service provider

Enterprise products

copper-phosphorus brazing filler metal

Copper-phosphorus brazing filler metal is an alloy brazing filler metal with copper and phosphorus as the main elements. It has good fluidity during brazing, low brazing temperature and self-brazing effect. When welding pure copper, it can be welded in normal atmosphere without brazing agent. It is suitable for resistance brazing, flame brazing and induction brazing of copper and copper alloys.

high copper brazing filler metal

Brass brazing filler metal is mainly used for flame brazing, high frequency induction brazing and resistance brazing and other rapid heating brazing process, brazing copper, copper alloy and steel, cast iron, hard alloy and so on.

silver brazing filler metal

Silver solder has excellent technological performance, good wettability and caulking performance, low melting point, corrosion resistance, easy conductivity, high mechanical strength, good plasticity, suitable for a variety of brazing methods, such as stainless steel, carbon steel, Cemented carbide, copper and copper alloys and most of the ferrous and non-ferrous metals.

vacuum brazing filler metal

The vacuum brazing filler metal has excellent process performance, suitable melting point, good wettability and caulking performance.

gold-based brazing filler metal

Gold-based brazing filler metal is based on gold, the main alloy elements are nickel, copper, palladium, zinc, copper, germanium, tin, etc., compared with silver brazing filler metal, has strong corrosion resistance, low vapor pressure and good fluidity and wettability characteristics.

aluminum brazing filler metal

Aluminum solder has good wettability and caulking performance, low melting point, corrosion resistance, which use more aluminum-silicon solder and zinc-aluminum solder.

nickel-based brazing filler metal

Nickel-based brazing filler metal is widely used in the brazing of stainless steel by adding alloying elements to reduce its melting point and improve its high temperature strength.

BGA Tin Ball

BGA solder balls are special solder balls used on the solder board before soldering the integrated circuit of the BGA package.

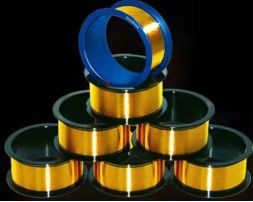

lead-free tin strip/Tin Wire

Widely used in military industry, precision electronic instruments, precision medical equipment, high-end electronic products, automotive electronics and other products of manual dip soldering and wave soldering tin.

tin strip containing lead/Tin Wire

It is widely used in manual dip soldering and wave soldering tin for military products, electronic and electrical products, high-end electronic products, home appliances, automotive electronics, and industrial electrical products.

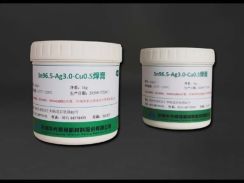

Solder paste

HG-X100A is a lead-free and non-cleaning solder paste, which has a wide process window and low void defects. It is compatible with Sn96.5-Ag3.0-Cu0.5, Sn98.5-Ag1.0-Cu0.5 and Sn99.0-Ag0.3-Cu0.7 alloys and is suitable for reflow soldering process of precision electronic devices.

composite brazing filler metal

Composite solder is composed of solder metal and its matching flux, which can be made into strips, wires, preformed rings and other shapes and specifications according to user requirements. It has the advantages of reducing welding steps, improving welding automation and efficiency, reducing and controlling the amount of flux, improving quality stability and so on.

Copper Alloy Welding Material

Copper and copper alloy welding with Welding materials wire, welding rod, flux, solvent, shielding gas, etc., in the copper alloy wire to join aluminum, silicon, manganese, phosphorus, tin and other elements, in order to strengthen the deoxidation, reduce the porosity in the weld.

copper-based brazing paste

Copper-based solder paste is made of alloy solder powder with copper and phosphorus as the main elements, adding active flux and binder independently developed by Fujing, which has the characteristics of good fluidity and excellent process performance.

Phosphorus-containing copper-based solder paste is suitable for brazing copper, copper alloy, silver alloy, etc. The solder paste has good wettability with the welded base metal and excellent welding strength.

silver-based brazing paste

Silver solder paste is made of alloy solder powder with silver or silver-based solid solution as the main alloy solder powder added with active solder and binder independently developed by Fujing. Fujing micro-elements can be added according to customer products to further improve welding strength and welding reliability.

flux

The melting point of the brazing filler is lower than that of the brazing filler metal, and it has good interfacial activity. It can effectively destroy or dissolve the surface oxide film of the workpiece and the brazing filler metal during brazing, which is conducive to the wetting and spreading of the liquid brazing filler metal on the surface of the brazing metal, so as to obtain the joint with excellent brazing quality.

high frequency induction welding equipment

Weldable materials: carbon steel, stainless steel, aluminum, copper and other metal alloys;

Equipment features: the current is highly concentrated in the welding zone, the heating speed is fast, the self-cooling effect of the weldment is strong, the heat affected zone is not only small, but also not easy to oxidize, and the organization and performance of the weld are good.

Handheld laser welding machine

Weldable materials: carbon steel, stainless steel, aluminum, copper and other metal alloys;

Equipment features: simple operation, fast welding speed, beautiful weld, no deformation, no blackening, large beam focusing penetration, small heat affected zone.

High frequency induction weldment processing

High frequency induction welding: the current is highly concentrated in the welding zone, the heating speed is fast, the self-cooling effect of the weldment is strong, the heat affected zone is not only small, but also not easy to oxidize, and the organization and performance of the weld are good. Suitable for high degree of mechanization or automation of pipe and profile production line, weldable materials for iron, aluminum, copper and other metal alloys.

Laser welding weldment processing

The operation is simple, the welding speed is fast, the weld is beautiful, no deformation, no blackening, the beam focusing penetration is large, and the heat affected zone is small. It is suitable for welding thin plate stainless steel, carbon steel and aluminum alloy.

Portable Aerobic Welding Torch suit:

Portable can be used for home decoration, after-sales maintenance, suit include: oxygen tank (empty)1, 1 aerobic small welding torch, 1 fierce fire valve, 2 rubber hoses and 1 oxygen bridge.

Built-in oxygen-free welding torch

Easy to carry, no need to carry oxygen tank, welding torchThe welding can be completed by fierce fire gas, and the maximum pipe diameter can be welded is 30mm.

Aerobic small welding torch

Used for installation and after-sales maintenance, portable,2 L oxygen line and hot gas (replacing butane gas).

Aerobic large gun

It is mostly used for site engineering installation and factory welding, and oxygen is mixed with acetylene or natural gas./Gas and other gas use.

Fierce valve

It is used for the skin pipe connection of fierce fire gas, with anti-tempering, decompression and constant pressure functions.

Special mixed gas for anaerobic welding gunFierce gas

Used to replace butane gas, self-developed formula, faster than the traditional welding gas combustion speed, higher calorific value, easier ignition.

Related News