Flame brazing equipment: efficient and reliable metal joining solutions

Release time:

2024-05-26

【Summary Description】 Flame brazing equipment is a kind of equipment widely used in the field of metal connection, which is highly respected for its high efficiency and reliability. The equipment heats the solder and the base metal through the flame to make it reach the molten state, so as to realize the connection of the metal parts. This article will introduce the working principle, application field and advantages of flame brazing equipment in detail. Working principle of 1. flame brazing equipment Flame brazing equipment is mainly composed of gas system, control system and welding gun. The gas system provides combustible gas and oxygen, and the gas ratio and flame size are adjusted by the control system. The welding gun is to spray the flame on the solder and the base metal, so that it is heated to a molten state, so as to achieve the connection. In the process of flame brazing, the equipment first preheats the brazing filler metal and the base metal to remove the oil and oxide on the surface. Next, the welding gun sprays a high-temperature flame to rapidly heat and melt the brazing filler metal and the base metal. In the molten state, the solder will penetrate into the gap of the base metal, forming a strong connection. Finally, the equipment through slow cooling, so that the weld gradually solidified, so as to complete the entire welding process. Application fields of 2. flame brazing equipment Flame brazing equipment is widely used in many fields. In the manufacturing industry, it is often used to connect various metal parts, such as steel pipes, steel plates, etc. In addition, flame brazing equipment also plays an important role in high-precision fields such as aerospace, shipbuilding, and automobile manufacturing. These areas require extremely high welding quality and accuracy, and flame brazing equipment can meet these stringent requirements. Advantages of 3. flame brazing equipment High efficiency: The flame brazing equipment has an efficient heating rate, which can quickly heat the brazing material and the base metal to the molten state, thereby improving production efficiency. Reliability: The equipment can realize high-quality metal connection, high weld strength, good sealing, and ensure the stability and safety of the product. Flexibility: The flame brazing equipment is suitable for metal materials of different materials and thicknesses, and has strong adaptability. At the same time, the equipment is simple to operate and convenient for workers to master. Environmental protection: Compared with traditional welding methods, flame brazing produces less exhaust gas and has less impact on the environment. 4. summary and prospect As an efficient and reliable metal joining solution, flame brazing equipment plays an important role in manufacturing and high-precision fields. With the continuous development of science and technology, flame brazing equipment will be further optimized and improved to bring more efficient and environmentally friendly welding technology to industrial production. In the future, we expect flame brazing equipment to show its excellent performance in more fields and contribute to the development of modern industry.

Flame brazing equipment is a kind of equipment widely used in the field of metal connection, which is highly respected for its high efficiency and reliability. The equipment heats the solder and the base metal through the flame to make it reach the molten state, so as to realize the connection of the metal parts. This article will introduce the working principle, application field and advantages of flame brazing equipment in detail.

Working principle of 1. flame brazing equipment

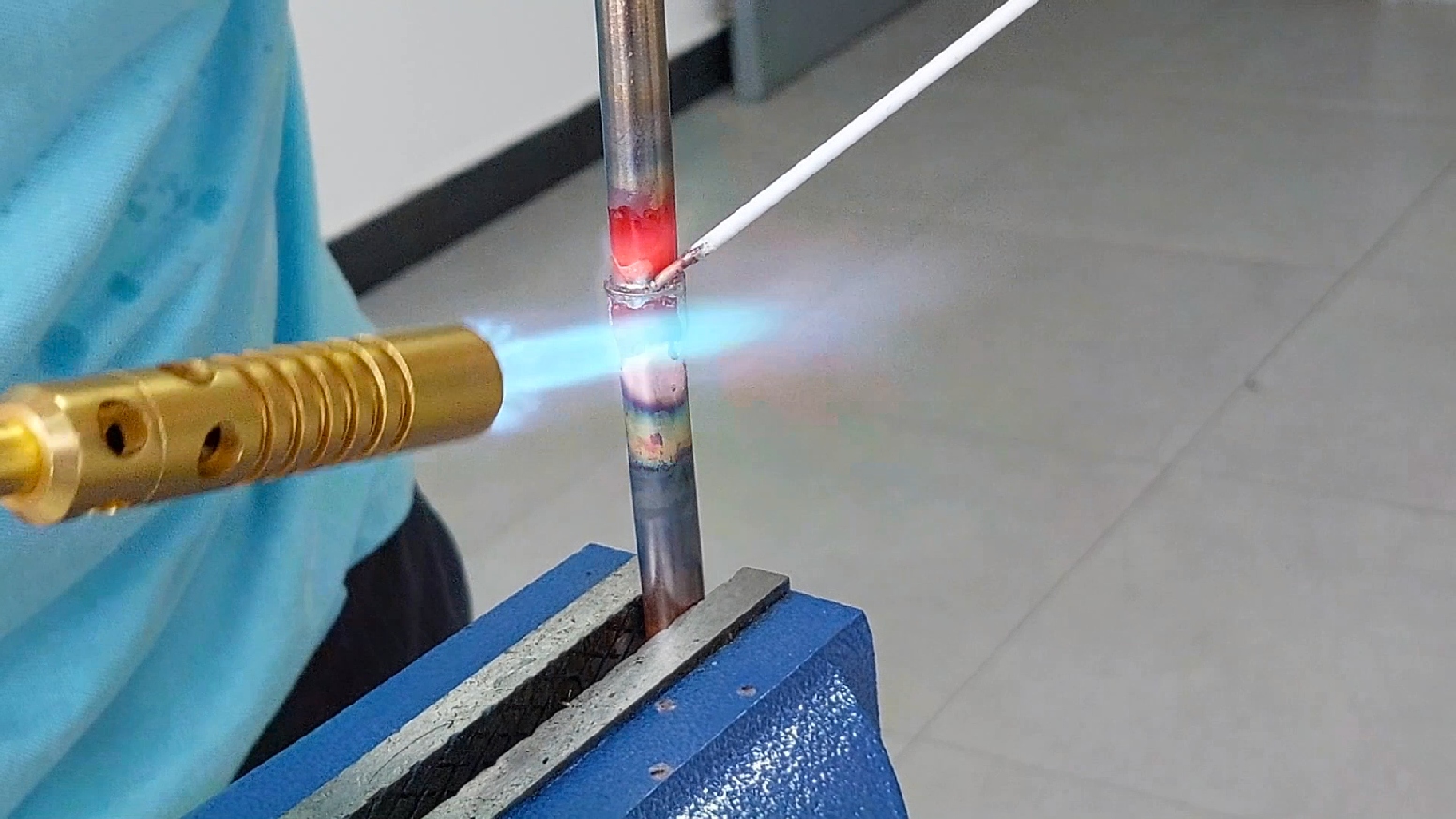

Flame brazing equipment is mainly composed of gas system, control system and welding gun. The gas system provides combustible gas and oxygen, and the gas ratio and flame size are adjusted by the control system. The welding gun is to spray the flame on the solder and the base metal, so that it is heated to a molten state, so as to achieve the connection.

In the process of flame brazing, the equipment first preheats the brazing filler metal and the base metal to remove the oil and oxide on the surface. Next, the welding gun sprays a high-temperature flame to rapidly heat and melt the brazing filler metal and the base metal. In the molten state, the solder will penetrate into the gap of the base metal, forming a strong connection. Finally, the equipment through slow cooling, so that the weld gradually solidified, so as to complete the entire welding process.

Application fields of 2. flame brazing equipment

Flame brazing equipment is widely used in many fields. In the manufacturing industry, it is often used to connect various metal parts, such as steel pipes, steel plates, etc. In addition, flame brazing equipment also plays an important role in high-precision fields such as aerospace, shipbuilding, and automobile manufacturing. These areas require extremely high welding quality and accuracy, and flame brazing equipment can meet these stringent requirements.

Advantages of 3. flame brazing equipment

- High efficiency: The flame brazing equipment has an efficient heating rate, which can quickly heat the brazing material and the base metal to the molten state, thereby improving production efficiency.

- Reliability: The equipment can realize high-quality metal connection, high weld strength, good sealing, and ensure the stability and safety of the product.

- Flexibility: The flame brazing equipment is suitable for metal materials of different materials and thicknesses, and has strong adaptability. At the same time, the equipment is simple to operate and convenient for workers to master.

- Environmental protection: Compared with traditional welding methods, flame brazing produces less exhaust gas and has less impact on the environment.

4. summary and prospect

As an efficient and reliable metal joining solution, flame brazing equipment plays an important role in manufacturing and high-precision fields. With the continuous development of science and technology, flame brazing equipment will be further optimized and improved to bring more efficient and environmentally friendly welding technology to industrial production. In the future, we expect flame brazing equipment to show its excellent performance in more fields and contribute to the development of modern industry.

Related News