Intelligent welding automation production line: efficient and accurate welding solutions

Release time:

2024-05-31

【Summary Description】 With the continuous progress of science and technology and the development of industrial automation, intelligent welding automation production line has become an indispensable part of modern manufacturing industry. By integrating advanced welding technology, sensors and control systems, this production line realizes the automation, precision and efficiency of the welding process, bringing unprecedented improvement to the manufacturing industry. Intelligent welding automation production line is mainly composed of welding robots, sensors, control systems and actuators. The welding robot is the core of the production line. It has a high degree of freedom and flexibility, and can perform precise welding operations in three-dimensional space. The sensor is used for real-time monitoring of various parameters in the welding process, such as temperature, current, voltage, etc., to ensure the stability and reliability of welding quality. The control system adjusts the motion trajectory and welding parameters of the welding robot in real time by receiving the feedback signal of the sensor to achieve the best welding effect. The actuator is responsible for completing specific welding actions, such as wire feeding, arc striking, arc extinguishing, etc. The advantages of intelligent welding automation production line are obvious. First of all, it greatly improves the welding efficiency and quality. Traditional welding methods are often affected by human factors, such as operation level, fatigue degree, etc., while intelligent welding automation production line completely eliminates these factors and realizes efficient and accurate welding. Secondly, intelligent welding automation production line reduces labor intensity and labor costs. Since the welding process is automated, the need for skilled welders can be reduced, thereby reducing labor costs. Finally, the intelligent welding automation production line also has a high degree of flexibility and scalability. It can be customized and optimized according to different welding needs and product characteristics to meet the diverse needs of customers. In practical application, intelligent welding automation production line has been widely used in automobile, ship, aerospace and other fields. Taking the automobile industry as an example, the intelligent welding automation production line can efficiently complete the welding work of the automobile body, improve the production efficiency and product quality. In the field of aerospace, intelligent welding automation production line can also ensure the accuracy and reliability of welding, and provide a strong guarantee for the safety of aircraft. However, intelligent welding automation production line also has certain challenges. For example, the high cost of R & D and manufacturing of equipment may increase the investment pressure of enterprises. In addition, the skill requirements for operators are relatively high, and professional training is required to master the operation and maintenance of equipment. In general, intelligent welding automation production line, as an efficient and accurate welding solution, has brought significant advantages to the modern manufacturing industry. With the continuous advancement of technology and the expansion of application fields, we have reason to believe that the intelligent welding automation production line will play a more important role in the future, and promote the development of industrial manufacturing in a more efficient and intelligent direction.

With the continuous progress of science and technology and the development of industrial automation, intelligent welding automation production line has become an indispensable part of modern manufacturing industry. By integrating advanced welding technology, sensors and control systems, this production line realizes the automation, precision and efficiency of the welding process, bringing unprecedented improvement to the manufacturing industry.

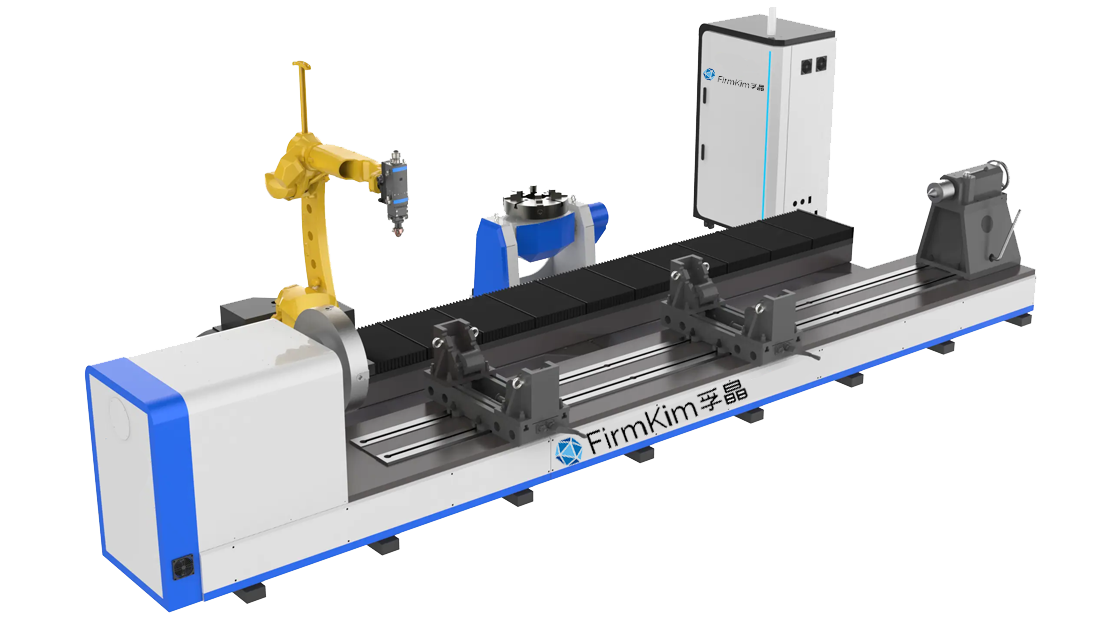

Intelligent welding automation production line is mainly composed of welding robots, sensors, control systems and actuators. The welding robot is the core of the production line. It has a high degree of freedom and flexibility, and can perform precise welding operations in three-dimensional space. The sensor is used for real-time monitoring of various parameters in the welding process, such as temperature, current, voltage, etc., to ensure the stability and reliability of welding quality. The control system adjusts the motion trajectory and welding parameters of the welding robot in real time by receiving the feedback signal of the sensor to achieve the best welding effect. The actuator is responsible for completing specific welding actions, such as wire feeding, arc striking, arc extinguishing, etc.

The advantages of intelligent welding automation production line are obvious. First of all, it greatly improves the welding efficiency and quality. Traditional welding methods are often affected by human factors, such as operation level, fatigue degree, etc., while intelligent welding automation production line completely eliminates these factors and realizes efficient and accurate welding. Secondly, intelligent welding automation production line reduces labor intensity and labor costs. Since the welding process is automated, the need for skilled welders can be reduced, thereby reducing labor costs. Finally, the intelligent welding automation production line also has a high degree of flexibility and scalability. It can be customized and optimized according to different welding needs and product characteristics to meet the diverse needs of customers.

In practical application, intelligent welding automation production line has been widely used in automobile, ship, aerospace and other fields. Taking the automobile industry as an example, the intelligent welding automation production line can efficiently complete the welding work of the automobile body, improve the production efficiency and product quality. In the field of aerospace, intelligent welding automation production line can also ensure the accuracy and reliability of welding, and provide a strong guarantee for the safety of aircraft.

However, intelligent welding automation production line also has certain challenges. For example, the high cost of R & D and manufacturing of equipment may increase the investment pressure of enterprises. In addition, the skill requirements for operators are relatively high, and professional training is required to master the operation and maintenance of equipment.

In general, intelligent welding automation production line, as an efficient and accurate welding solution, has brought significant advantages to the modern manufacturing industry. With the continuous advancement of technology and the expansion of application fields, we have reason to believe that the intelligent welding automation production line will play a more important role in the future, and promote the development of industrial manufacturing in a more efficient and intelligent direction.

Related News