Title: Innovation and Progress of Welding Robot Technology

Release time:

2024-06-03

【Summary Description】 With the rapid development of science and technology, welding robot technology is more and more widely used in modern manufacturing industry. In recent years, welding robot technology has been continuously updated and iterated, bringing unprecedented changes to the manufacturing industry. This article will explore the latest update in welding robot technology and its impact on the industry. Development of 1. Welding Robot Welding robot is an industrial robot that can automatically perform welding tasks. Since its inception in the 1980 s, welding robots have played an increasingly important role in the manufacturing industry. With the continuous progress of technology, the welding robot has gradually developed from the initial simple repetitive action to the ability of highly intelligent and autonomous. Latest updates in 2. welding robot technology Introduction of visual recognition technology In recent years, visual recognition technology has been widely used in welding robots. Equipped with high-resolution cameras and advanced image processing algorithms, the welding robot can identify the position, shape and size of the weld in real time, so as to accurately control the welding trajectory. The introduction of this technology has greatly improved the accuracy and efficiency of welding. Optimization of Intelligent Control Algorithm With the rapid development of artificial intelligence technology, the control algorithm of welding robot is constantly optimized. The new generation of welding robot adopts more advanced control strategies, such as fuzzy control, neural network control, etc., so that the robot can adjust the welding parameters autonomously according to the real-time welding situation to ensure the stability and reliability of welding quality. The rise of collaborative robots Collaborative robot (Cobots) is a new type of welding robot in recent years. They are designed to work collaboratively with human workers without the need for special safety isolation. Collaborative robots are highly flexible and safe, and can seamlessly interface with human workers to complete complex welding tasks. The emergence of this technology makes human-machine collaboration possible and further improves production efficiency. Impact of 3. welding robot technology updates The continuous updating of welding robot technology has had a profound impact on the manufacturing industry. First of all, the introduction of new technologies has improved welding quality and efficiency and reduced production costs. Secondly, the wide application of intelligent welding robots has promoted the process of automation and intelligence in the manufacturing industry, creating a greater competitive advantage for enterprises. Finally, the rise of collaborative robots has improved the working environment, reduced the labor intensity of workers, and improved job satisfaction. 4. looking to the future With the continuous progress and innovation of science and technology, we have reason to believe that welding robot technology will continue to grow. In the future, welding robots will be more intelligent, autonomous and collaborative, bringing more revolutionary changes to the manufacturing industry. At the same time, we should also pay attention to the sustainable development of welding robot technology, and strive to achieve the harmonious coexistence of human and robot. In short, the innovation and progress of welding robot technology has brought significant benefits and changes to the manufacturing industry. Let's look forward to welding robots playing a more important role in the future manufacturing industry!

With the rapid development of science and technology, welding robot technology is more and more widely used in modern manufacturing industry. In recent years, welding robot technology has been continuously updated and iterated, bringing unprecedented changes to the manufacturing industry. This article will explore the latest update in welding robot technology and its impact on the industry.

Development of 1. Welding Robot

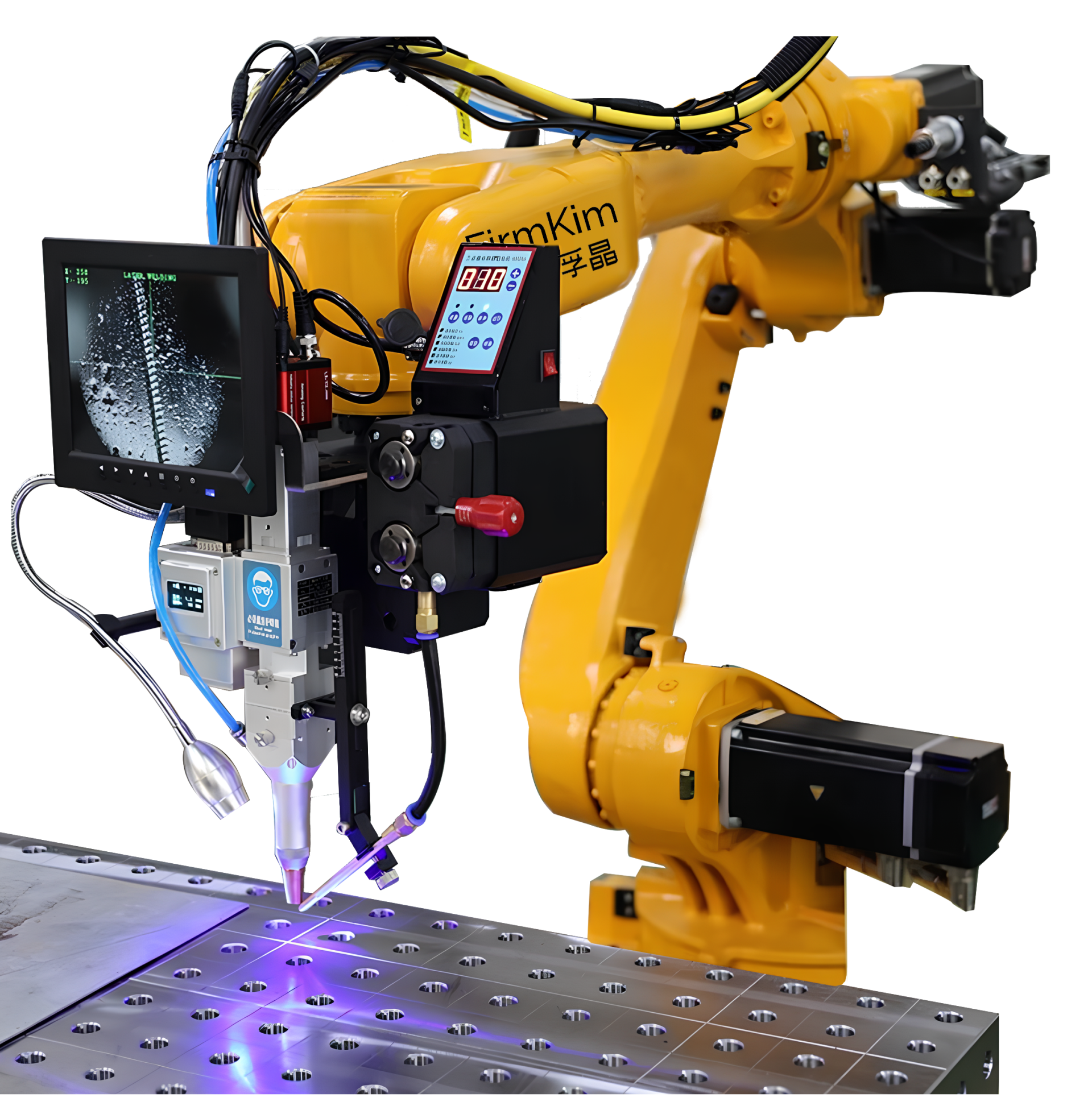

Welding robot is an industrial robot that can automatically perform welding tasks. Since its inception in the 1980 s, welding robots have played an increasingly important role in the manufacturing industry. With the continuous progress of technology, the welding robot has gradually developed from the initial simple repetitive action to the ability of highly intelligent and autonomous.

Latest updates in 2. welding robot technology

- Introduction of visual recognition technology

In recent years, visual recognition technology has been widely used in welding robots. Equipped with high-resolution cameras and advanced image processing algorithms, the welding robot can identify the position, shape and size of the weld in real time, so as to accurately control the welding trajectory. The introduction of this technology has greatly improved the accuracy and efficiency of welding.

- Optimization of Intelligent Control Algorithm

With the rapid development of artificial intelligence technology, the control algorithm of welding robot is constantly optimized. The new generation of welding robot adopts more advanced control strategies, such as fuzzy control, neural network control, etc., so that the robot can adjust the welding parameters autonomously according to the real-time welding situation to ensure the stability and reliability of welding quality.

- The rise of collaborative robots

Collaborative robot (Cobots) is a new type of welding robot in recent years. They are designed to work collaboratively with human workers without the need for special safety isolation. Collaborative robots are highly flexible and safe, and can seamlessly interface with human workers to complete complex welding tasks. The emergence of this technology makes human-machine collaboration possible and further improves production efficiency.

Impact of 3. welding robot technology updates

The continuous updating of welding robot technology has had a profound impact on the manufacturing industry. First of all, the introduction of new technologies has improved welding quality and efficiency and reduced production costs. Secondly, the wide application of intelligent welding robots has promoted the process of automation and intelligence in the manufacturing industry, creating a greater competitive advantage for enterprises. Finally, the rise of collaborative robots has improved the working environment, reduced the labor intensity of workers, and improved job satisfaction.

4. looking to the future

With the continuous progress and innovation of science and technology, we have reason to believe that welding robot technology will continue to grow. In the future, welding robots will be more intelligent, autonomous and collaborative, bringing more revolutionary changes to the manufacturing industry. At the same time, we should also pay attention to the sustainable development of welding robot technology, and strive to achieve the harmonious coexistence of human and robot.

In short, the innovation and progress of welding robot technology has brought significant benefits and changes to the manufacturing industry. Let's look forward to welding robots playing a more important role in the future manufacturing industry!

Related News