Laser Cladding Metal Surface Treatment Technology: Principle, Application Development and Welding Substitute Processing

Release time:

2024-06-05

【Summary Description】 As an advanced metal surface treatment technology, laser cladding technology has been widely used in industrial production in recent years. In this paper, the principle, characteristics, application fields and future development trend of laser cladding technology are discussed in detail. Principle of 1. Laser Cladding Technology Laser cladding technology is the use of high-energy laser beam to melt the alloy powder of specific components, and rapid solidification on the surface of the metal substrate, so as to form a high-performance coating. This technology can significantly improve the hardness, wear resistance, corrosion resistance and oxidation resistance of the metal surface by changing the chemical composition and structure of the coating. Characteristics of 2. laser cladding technology High energy density: The laser beam has a high energy density, which can quickly melt the alloy powder and achieve metallurgical bonding with the substrate. Rapid solidification: The rapid solidification in the laser cladding process is beneficial to refine the structure and improve the mechanical properties and corrosion resistance of the coating. Adjustable coating composition: By adjusting the composition of the alloy powder, a coating with specific properties can be obtained to meet the needs of different working conditions. Small heat-affected zone: The heat input in the laser cladding process is small, and the heat-affected zone on the substrate is small, which reduces the risk of deformation and cracking. Application fields of 3. laser cladding technology Aerospace field: Aerospace vehicles have extremely high requirements for material performance. Laser cladding technology can significantly improve the wear resistance, corrosion resistance and high temperature oxidation resistance of parts, and extend the service life. Petrochemical industry: Petrochemical equipment often faces harsh working environments. Laser cladding technology can form high-performance coatings on the surface of the equipment to improve its corrosion resistance and service life. In the field of mechanical manufacturing: laser cladding technology can be used to repair worn mechanical equipment parts, restore their dimensional accuracy and performance, and reduce maintenance costs. Future Development of 4. Laser Cladding Technology With the continuous development of science and technology, laser cladding technology will develop in the following directions: Automation and intelligence: the introduction of advanced control systems and sensor technology to achieve automation and intelligent monitoring of the laser cladding process, improve production efficiency and coating quality. Research and development of new materials and new processes: Explore more new materials and new processes suitable for laser cladding technology to meet the needs of different industrial fields. Green environmental protection: research and development of low energy consumption, low pollution laser cladding equipment and process, reduce the environmental load in the production process. Expand the application field: With the continuous improvement and innovation of technology, laser cladding technology is expected to expand to more fields, such as biomedicine, electronic information, etc. In short, laser cladding metal surface treatment technology, as an efficient and flexible surface modification method, has a wide range of applications in many fields. With the continuous progress and innovation of science and technology, laser cladding technology will continue to grow and inject new vitality into the sustainable development of industrial production.

As an advanced metal surface treatment technology, laser cladding technology has been widely used in industrial production in recent years. In this paper, the principle, characteristics, application fields and future development trend of laser cladding technology are discussed in detail.

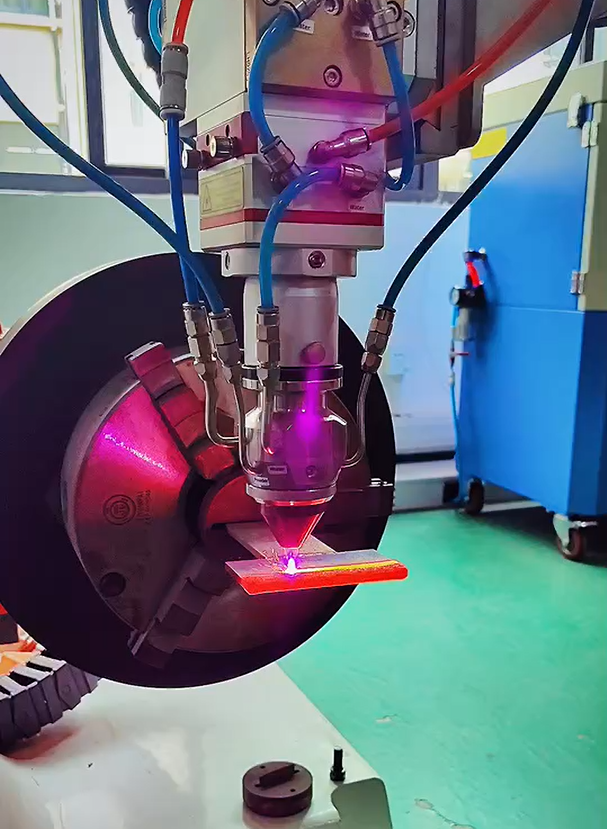

Principle of 1. Laser Cladding Technology

Laser cladding technology is the use of high-energy laser beam to melt the alloy powder of specific components, and rapid solidification on the surface of the metal substrate, so as to form a high-performance coating. This technology can significantly improve the hardness, wear resistance, corrosion resistance and oxidation resistance of the metal surface by changing the chemical composition and structure of the coating.

Characteristics of 2. laser cladding technology

- High energy density: The laser beam has a high energy density, which can quickly melt the alloy powder and achieve metallurgical bonding with the substrate.

- Rapid solidification: The rapid solidification in the laser cladding process is beneficial to refine the structure and improve the mechanical properties and corrosion resistance of the coating.

- Adjustable coating composition: By adjusting the composition of the alloy powder, a coating with specific properties can be obtained to meet the needs of different working conditions.

- Small heat-affected zone: The heat input in the laser cladding process is small, and the heat-affected zone on the substrate is small, which reduces the risk of deformation and cracking.

Application fields of 3. laser cladding technology

- Aerospace field: Aerospace vehicles have extremely high requirements for material performance. Laser cladding technology can significantly improve the wear resistance, corrosion resistance and high temperature oxidation resistance of parts, and extend the service life.

- Petrochemical industry: Petrochemical equipment often faces harsh working environments. Laser cladding technology can form high-performance coatings on the surface of the equipment to improve its corrosion resistance and service life.

- In the field of mechanical manufacturing: laser cladding technology can be used to repair worn mechanical equipment parts, restore their dimensional accuracy and performance, and reduce maintenance costs.

Future Development of 4. Laser Cladding Technology

With the continuous development of science and technology, laser cladding technology will develop in the following directions:

- Automation and intelligence: the introduction of advanced control systems and sensor technology to achieve automation and intelligent monitoring of the laser cladding process, improve production efficiency and coating quality.

- Research and development of new materials and new processes: Explore more new materials and new processes suitable for laser cladding technology to meet the needs of different industrial fields.

- Green environmental protection: research and development of low energy consumption, low pollution laser cladding equipment and process, reduce the environmental load in the production process.

- Expand the application field: With the continuous improvement and innovation of technology, laser cladding technology is expected to expand to more fields, such as biomedicine, electronic information, etc.

In short, laser cladding metal surface treatment technology, as an efficient and flexible surface modification method, has a wide range of applications in many fields. With the continuous progress and innovation of science and technology, laser cladding technology will continue to grow and inject new vitality into the sustainable development of industrial production.

Related News